Rail Insert® Welding

Why?

Maintaining CWR under the strains of modern tonnage, combined with aging rail infrastructure, necessitates a proactive approach. As EFB welding continues to prove to be the most efficient way to remove joints and defects in CWR, there are still various factors that inhibit achieving a maximally efficient program, with maximum quality.

One of the largest struggles in the PSR (Precision Scheduled Railroading) era is having enough plug-rails on-hand to replace all defects in any given territory. For a plug-rail to be an appropriate candidate for installation, it needs to be of the same parent rail size, have headwear within 5 mm of the parent material, be of the same metallurgical grade or better, must be UT tested and marked as such (if it’s a previously worn rail), and of sufficient length.

Railroads often spend a lot of production time hunting for plug-rails. This limits the cost benefits of EFB repair welding. And when plug-rails are found, they may be beneath or beyond the head-wear mismatch limit. Even at the head-wear mismatch limit of 5 mm, the increased amount of finish-grinding to achieve proper geometric profile, which further reduces the gang’s speed to move to the next location. Additionally, defects that propagate from the underside of the ball of the rail at the edge of the weld material due to shearing railheads that are offset.

What?

One Rail Group, LLC is proud to offer their patented Rail Inserts®. Rail Inserts® are plug-rails that are milled to various depths that match both existing parent-rail headwear (within 2mm) as well as wheel-worn rail profile. Starting with a new section of premium rail ensures that the metallurgy is equal to or better than the parent-rail. Using carbide milling to create rails with a headwear from #136RE – 3mm, down to #136RE – 16mm (in 2mm increments), while also adjusting the head to a worn profile to get the best possible running surface match. The rails are then cut down to Rail Insert® plug lengths of 5 feet.

This length creates many customer benefits, including:

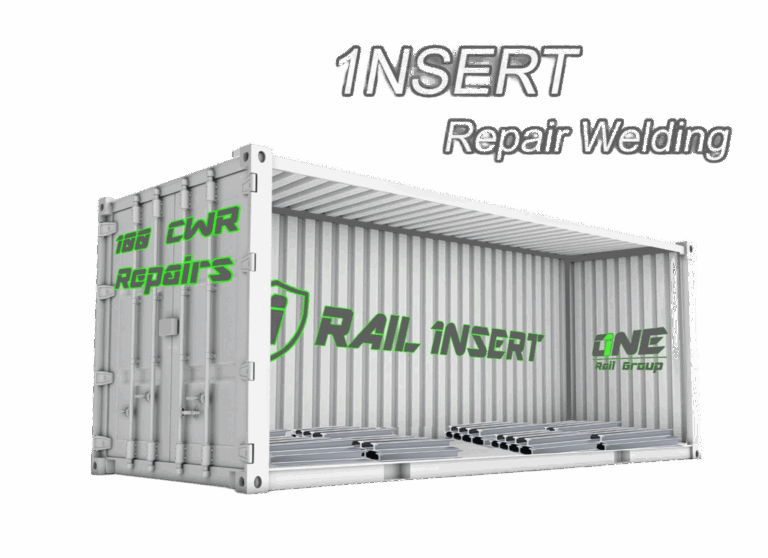

♣ Reduced Shipping Costs – We can ship up to 100 inserts in a standard 20’ steel container to any Railroad Depot location

♣ Efficient Distribution – Enough rail inserts for multiple days of production can be loaded into the section truck prior to leaving the depot, so customers do not need to use a grapple truck to find, transport, and distribute plug-rails ahead of the crew

♣ Safer Handling – Working with smaller rails prevents grapple trucks and other cranes from swinging longer pieces of rail around the crew during unloading and installation.

♣ Less Waste – Defect repair and joint removal can be done with up to 75% less rail waste.

♣ Smaller Crew Size – Using Rail Inserts eliminates the need to have a grapple truck and additional CDL operator onsite.

♣ Shorter Work Windows – Since the amount of rail being exchanged is reduced, there are less spikes to pull, anchors to remove, and while having a better head-wear match, less finish grinding is required. Since these lengths allow the free weld to still fit within the Rail Puller when making a closure, there is less time waiting for the first weld to cool prior to putting it into tension.

How?

The question is: How can One Rail Group ensure that such a short rail is welded within the proper geometry on both welds? The answer is: ONE’s patented Auto-Crowning system.

By having a mismatch that is 3mm or less, the heads of the rail can be aligned within the offset in the base*. While the heads are aligned, the Auto-Crowning system, using 4-points of vertically adjustable contact, and hydraulically activated vertical jack cylinders, can push and hold the rail at the proper crown, without worrying about lifting the entire Rail Insert off the ground. It is also much SAFER and much FASTER than using hand-jacks and wedges. It also provides a more consistent finished product because the machine holds the crown alignment all the way through the upsetting process. Short plug-rails are difficult to work with because of the small vertical move on one end which translates to a much larger change in rail slope, and a more extreme crown. Further, it’s easy to lift the rail completely off the ground while jacking, since the rail is not heavy enough to hold itself down.

Get ahead of your joint and defect count using ONE’s Turnkey Rail Insert® Gang. A full service and material offering that doesn’t require any support from the customer, other than providing and EIC and track-time. Simply provide the quantity of defects, location, rail size, and measured headwear at each defect location. ONE will put together the most efficient package for your territory. No more hunting for matching plug-rails, no more concerns about whether a worn plug-rail has been UT tested, and no more tying up your section gang to find and distribute worn rails. Put your repair welding programs in overdrive with Rail Inserts.

*3mm is the maximum allowed base offset; however, ONE recommends no more than 2mm to prevent rails from pushing up or diving due to uneven resistance during the upset process from the uneven base alignment.

Why?

Maintaining CWR under the strains of modern tonnage, combined with aging rail infrastructure, necessitates a proactive approach. As EFB welding continues to prove to be the most efficient way to remove joints and defects in CWR, there are still various factors that inhibit achieving a maximally efficient program, with maximum quality.

One of the largest struggles in the PSR (Precision Scheduled Railroading) era is having enough plug-rails on-hand to replace all defects in any given territory. For a plug-rail to be an appropriate candidate for installation, it needs to be of the same parent rail size, have headwear within 5 mm of the parent material, be of the same metallurgical grade or better, must be UT tested and marked as such (if it’s a previously worn rail), and of sufficient length.

Railroads often spend a lot of production time hunting for plug-rails. This limits the cost benefits of EFB repair welding. And when plug-rails are found, they may be beneath or beyond the head-wear mismatch limit. Even at the head-wear mismatch limit of 5 mm, the increased amount of finish-grinding to achieve proper geometric profile, which further reduces the gang’s speed to move to the next location. Additionally, defects that propagate from the underside of the ball of the rail at the edge of the weld material due to shearing railheads that are offset.

What?

One Rail Group, LLC is proud to offer their patented Rail Inserts®. Rail Inserts® are plug-rails that are milled to various depths that match both existing parent-rail headwear (within 2mm) as well as wheel-worn rail profile. Starting with a new section of premium rail ensures that the metallurgy is equal to or better than the parent-rail. Using carbide milling to create rails with a headwear from #136RE – 3mm, down to #136RE – 16mm (in 2mm increments), while also adjusting the head to a worn profile to get the best possible running surface match. The rails are then cut down to Rail Insert® plug lengths of 5 feet.

This length creates many customer benefits, including:

♣ Reduced Shipping Costs – We can ship up to 100 inserts in a standard 20’ steel container to any Railroad Depot location

♣ Efficient Distribution – Enough rail inserts for multiple days of production can be loaded into the section truck prior to leaving the depot, so customers do not need to use a grapple truck to find, transport, and distribute plug-rails ahead of the crew

♣ Safer Handling – Working with smaller rails prevents grapple trucks and other cranes from swinging longer pieces of rail around the crew during unloading and installation.

♣ Less Waste – Defect repair and joint removal can be done with up to 75% less rail waste.

♣ Smaller Crew Size – Using Rail Inserts eliminates the need to have a grapple truck and additional CDL operator onsite.

♣ Shorter Work Windows – Since the amount of rail being exchanged is reduced, there are less spikes to pull, anchors to remove, and while having a better head-wear match, less finish grinding is required. Since these lengths allow the free weld to still fit within the Rail Puller when making a closure, there is less time waiting for the first weld to cool prior to putting it into tension.

How?

The question is: How can One Rail Group ensure that such a short rail is welded within the proper geometry on both welds? The answer is: ONE’s patented Auto-Crowning system.

By having a mismatch that is 3mm or less, the heads of the rail can be aligned within the offset in the base*. While the heads are aligned, the Auto-Crowning system, using 4-points of vertically adjustable contact, and hydraulically activated vertical jack cylinders, can push and hold the rail at the proper crown, without worrying about lifting the entire Rail Insert off the ground. It is also much SAFER and much FASTER than using hand-jacks and wedges. It also provides a more consistent finished product because the machine holds the crown alignment all the way through the upsetting process. Short plug-rails are difficult to work with because of the small vertical move on one end which translates to a much larger change in rail slope, and a more extreme crown. Further, it’s easy to lift the rail completely off the ground while jacking, since the rail is not heavy enough to hold itself down.

Get ahead of your joint and defect count using ONE’s Turnkey Rail Insert® Gang. A full service and material offering that doesn’t require any support from the customer, other than providing and EIC and track-time. Simply provide the quantity of defects, location, rail size, and measured headwear at each defect location. ONE will put together the most efficient package for your territory. No more hunting for matching plug-rails, no more concerns about whether a worn plug-rail has been UT tested, and no more tying up your section gang to find and distribute worn rails. Put your repair welding programs in overdrive with Rail Inserts.

*3mm is the maximum allowed base offset; however, ONE recommends no more than 2mm to prevent rails from pushing up or diving due to uneven resistance during the upset process from the uneven base alignment.